Contender Tours the Moots Factory

Few bikes elicit lust quite like Moots. The luxury brand handmakes each bicycle with artisan precision in their Steamboat Springs factory in Colorado as titanium frames and hand-picked components work together to create a bicycle company with a loyal following. Ride a Moots and you might spend as much time talking about your bike as you will riding it.

Moots creates roughly 5 frames per workday. Compared to the big guns in the industry, that’s hardly a blip on the production run. But with each frame getting personal attention from dedicated craftspeople you get a work of art instead of the same bike as half of the people in your group ride.

Recently, Contender Bicycles’ Berin Klawiter spent a week in Steamboat Springs - his hometown - and talked the folks at Moots into letting him wander around with a camera taking pictures and talking shop. Berin feels at home behind a camera lens and on a bike saddle. That’s probably why we hired him to be the ‘pictures’ part of our marketing and e-commerce team.

Anyhow, with hundreds of pictures at his disposal, here’s a look at the Moots factory in Steamboat along with some thoughts Berin shared following his tour of the titanium paradise. This might be a good time to put on a face mask because there's a high likelihood of drooling as you scroll down the page.

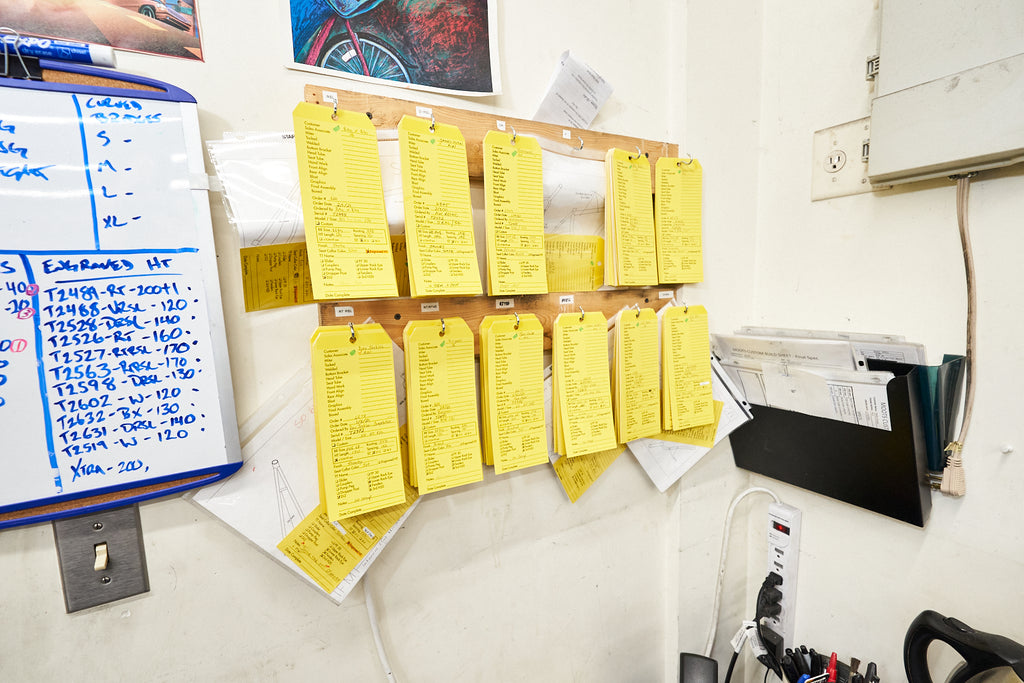

At Moots, everything starts with a yellow card. The yellow card is a build card that accompanies each Moots build. For the most part, printing out this yellow card was really the only part of a bike build that is done by a computer.

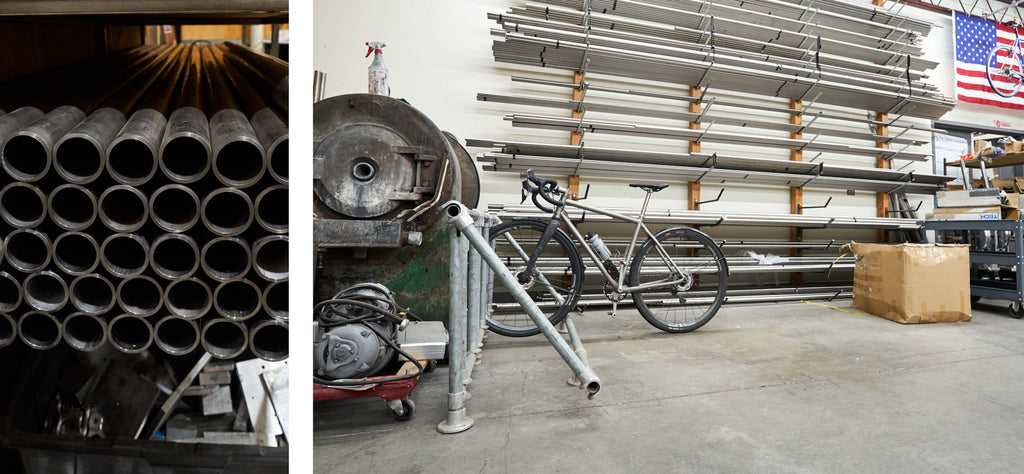

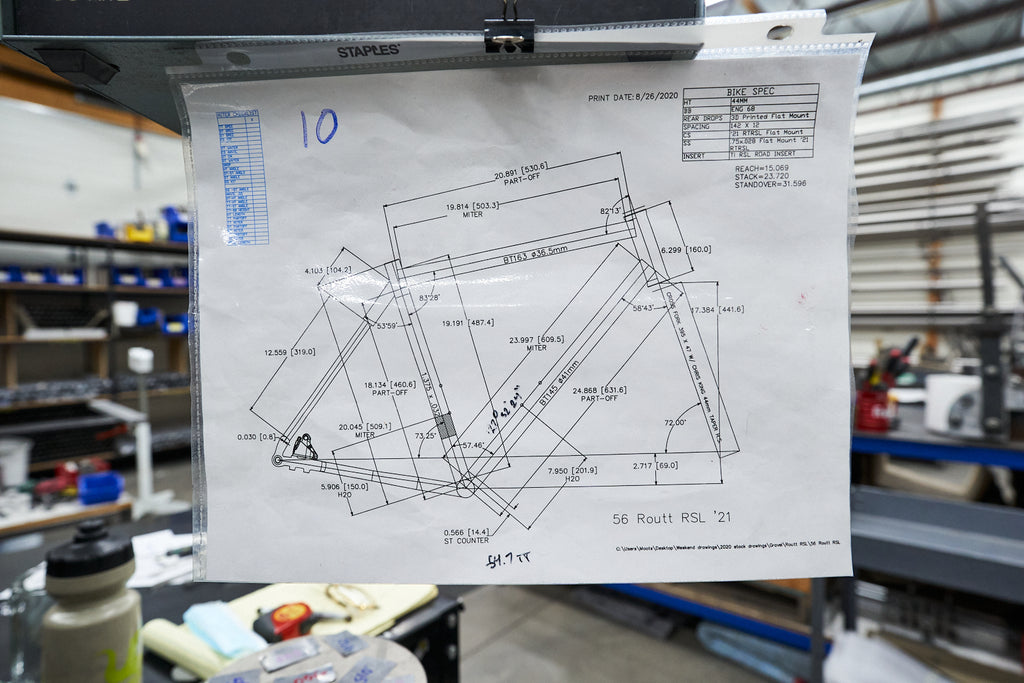

Each Moots starts out as a pile of titanium pipes. Following the specifications on the yellow build card, Moots' skilled team bends and cuts each piece required for a frame to specification by hand. This means each bike can be custom built to fit without altering Moots manufacturing process. Aside from a few small parts that are 3D printed, Moots manufactures each part of the frame in its factory.

Moots' small team of welders tacks each frame together. Welding titanium is no easy process, as each frame must be sealed airtight before it is filled with argon gas. Unlike other materials like aluminum or steel, titanium cannot be welded under oxygen or the welds won't hold. Argon provides the perfect environment for the welds to occur. This also means each Moots welder is highly skilled in their craft, each having started off as a tack welder before they can graduate to become a finish welder. During the welding process frames are checked against a perfectly flat surface to ensure the bike will be precise in its specifications. Once each piece has been assembled and welded to perfection frames are taken to be polished and finished.

If a bike isn't perfect down to the welds and specifications listed on the yellow card it is scrapped and the whole process starts again. This ensures only the best bikes wear the Moots headbadge.

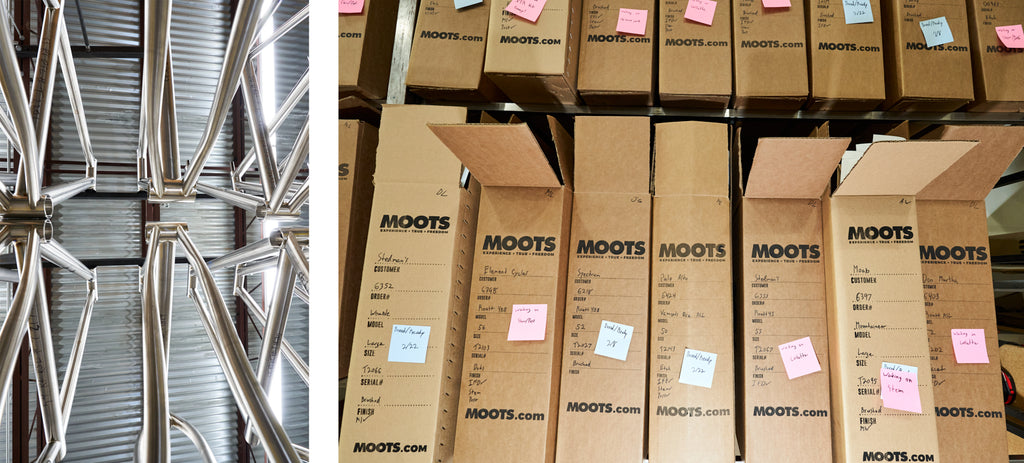

Here bikes are sandblasted and acid-washed creating a perfect polish. After this process is completed a Moots frame is no longer touched by a bare human hand until it reaches the customer (or bike shop completing the build in our case). Considering each Moots frame is custom built to customer specifications, most personalizations occur in the finishing process. These customizations include choosing how the frame is finished including ionizing the titanium to create some pretty rad patterns with the logo. Moots also refinishes a lot of old bikes restoring them to their original titanium shine.

The last step in the manufacturing process is boxing the frames up and sending them to the customers. While most Moots frames are built to order, Moots only ships out a few fully assembled bikes. Most frames are sent directly to bike shops like Contender Bicycles where they are assembled with curated components and parts and delivered to our customers.

Contender Bicycles takes pride in offering some of the finest bikes on the market. Moots, undeniably, fits that description and we are thrilled to be one of the select bike shops in our region offering these bikes. If you are interested in having a custom Moots created for you, stop by the shop to chat with our Pro Build experts.

Have any questions about Moots? Give us a call or send us an email any time to info@contenderbicycles.com.

Photos by Berin Klawiter.

Moots bikes are the most wonderful bike in the world and I love it. Please can moots help me to learn how to make bicycle, please, please and please, I really want to learn how to make bicycle. Thanks. I look forward to hear from moots

Gerald Ihezuo on

Moots bikes are the most wonderful bike in the world and I love it. Please can moots help me to learn how to make bicycle, please, please and please, I really want to learn how to make bicycle. Thanks. I look forward to hear from moots

Gerald Ihezuo on

Thomas,

happy to hear. Your bike will be rad for sure!

Alvin on

Last week,I ordered a Moot’s through Contender. I CAN’T to get it and feel its smooth subtle ride.

Thomas on